https://embed.notionlytics.com/wt/ZXlKd1lXZGxTV1FpT2lJd05UQmhObVEzTUdZek5XTTBZakF5T0RreU9HRmxNbUV6TmpFeVl6RmhaU0lzSW5kdmNtdHpjR0ZqWlZSeVlXTnJaWEpKWkNJNklqbHpjVk52YW1nMU4zbDZXV1p3UjJ4QlZVSm1JbjA9

<aside> 🗣 The Birth of Innovation

Nearly every organization wants to be more innovative and produce their industry’s Next Big Thing – something better, cheaper, faster, and maybe even disruptive.

**Here are the** critical ingredients enterprise organizations often use to innovate internally:

*Only the best ideas can make it all the way to the top.*

When discussing these particulars of team, process, and culture, the conversation can quickly become nuanced and organization-specific. From skunk works to R&D labs and innovation colonies, there’s no “one size fits all” form of internal innovation, and the sustainability of any pipeline design must fit within an organization’s culture. One of the most important variables that a leader can control is when, where, and how an innovation pipeline is gated.

A gate (also commonly called a stage, phase, or innovation gate) is exactly what it sounds like: an intentional barrier that the innovating team must pass, to push forward on a given concept. Traditionally, such a gate could be something like a full business case presentation to an organization’s leadership. More recently however, teams commonly present working prototypes in addition to customer feedback and other data. Products can get to market more quickly this way.

</aside>

However, such flexibility can come with a price. Gates can sometimes increase risk by:

Gates are valuable to scaled organizations. They grant increased control and decrease risk by empowering leadership to:

🚨 Remember: In the marketplace, the only gates an entrepreneur faces are finding resources, finding the ideal market for their product, and finding the confidence to push through failures. 🚨

Risk and failure are inherent parts of innovation. Gates both decrease and increase risk, depending how judiciously they’re applied. Limiting the number of gates is counterintuitive for many organizations because in a scaled enterprise, control, efficiency, and due diligence traditionally increase the odds of success. However, within an innovation pipeline, too much control inadvertently causes more risk.

Ultimately, what really defines how – or if – an organization can successfully innovate is the organization’s culture. An open-minded, progressive company culture with many gates will still be more effective than a fearful one with a fully autonomous lab. Culture and processes tend to go hand in hand, so instituting a formalized pipeline can help transform an organization’s culture, particularly if its design accounts for the existing propensity for control and tolerance of risk.

It can be a tricky balancing act, but the rewards are often worth it. Let’s examine the pipeline gating practices of four innovative enterprise organizations. These examples are not intended to be applied directly; rather, they demonstrate how different organizations approach risk through gating their pipelines.

<aside> 1️⃣ Philips Experience Design’s Cocreate

Known for its unique method, the Philips Experience Design team states that, “Effective innovation calls for a collaborative design approach that puts people at the center from the very start.” Their process doubles down on that.

Called Cocreate, this human-centered perspective on innovation requires input from a spectrum of collaborators. From patients and consumers to clinicians, they tackle product creation from a holistic understanding.

Under this umbrella, there’s a 4-part process that allows the natural tensions of each step and differing points of view to act as checks and balances. There’s discover, or immersion to understand the context of consumer lives, frame, where challenges & opportunities are identified, ideate, where a range of solutions are offered, and finally build, where prototypes are user-tested.

</aside>

[***Learn more about Philips’s process here.***](<https://www.philips.com/a-w/about/innovation/experience-design/our-approach>)

Strengths of Philips’s Cocreate

Cocreate’s approach ensures that the products being developed are battle tested from a variety of different angles. These various stages of assessment help to identify and address potential issues early-on and mitigate later risks. And because there’s involvement and participation across teams, there’s greater alignment on the products that make it to testing.

Challenges of Philips's Cocreate

The downside to these various collaborative stages is that they can result in a loss of flexibility and agility that reduces the ability to integrate new information and respond to changing market conditions. This is a danger in any tiered process – when instituting one at your own org make sure that the benefits of collaboration aren’t outweighed by a bureaucracy you’ve unintentionally created.

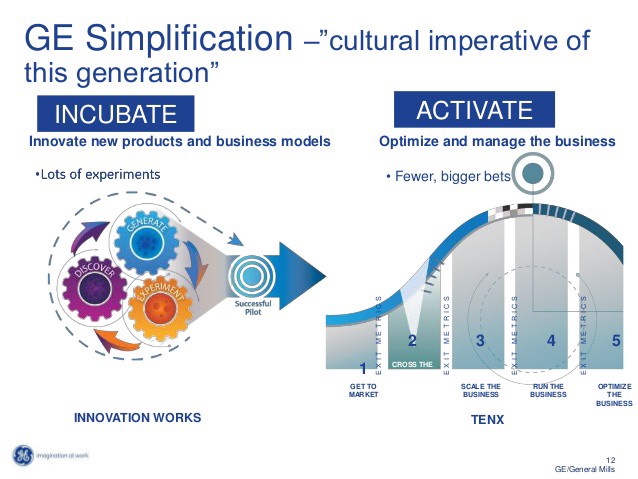

<aside> 2️⃣ GE’s FastWorks Program

With three major gates, GE FastWorks–a global innovation program built upon Lean Startup principles – lies somewhere in the middle of our framework. Designed to be dispensed into individual business units, it more closely resembles an internal coaching service than a lab:

To access FastWorks, employees pitch their ideas to a Growth Board (existing in each business unit), which approves or rejects potential projects. Once ideas are selected, the team tests and proves their viability through continuous customer interaction.

Once this phase is complete, the board reviews the idea again, this time with an emphasis on creating an inexpensive minimum viable product that will test the fundamental theses. Once approved, more funds are unlocked to build–and continue to test–an MVP. And when built, the team goes through one more round of board approvals before mass production or scale can begin.

</aside>

*[**Learn more about GE’s process here.**](<http://www.slideshare.net/bmacarolinas/evangelizing-and-leading-the-strategic-role-of-marketing-in-innovation-by-stephen-liguori>)*

Strengths of GE’s Three Gate

With this hands-on approach, FastWork coaches provide more real-time feedback throughout the pipeline, reducing MVP feature-creep and navigating away from other common pitfalls. GE’s process encourages acceptance from the top (sponsorship, understanding and ongoing education about lean principles) and support to the bottom (giving teams tools, training, and funding).

By distributing innovation and project responsibility across the company, FastWorks prevents learnings from being siloed within a single lab, or innovating within a vacuum. And beyond these gates, teams had additional autonomy, allowing them to pivot without added bureaucracy.

Challenges of GE’s Three Gate

Reports of the FastWorks pipeline point to a highly competitive atmosphere for employees, where securing approval for the program is likened to facing the formality of a Shark Tank-like pitch. Within GE’s corporate culture, this seems like a perfect match –but it’s potentially problematic for less internally-competitive organizations.

<aside> 3️⃣ 3M’s 3-Part Approach

3M’s approach relies, yes, on a 3-part team. Comprised of scouts, entrepreneurs, and implementers, these tripartite working units come together for a project, see it through to completion, and then disband until it’s time to face the next challenge.

Within this construction, there are multiple pathways to innovation, like close market interactions, deep research, and serendipitous discovery. And they’re all based on the belief that anyone within the company has the potential to light the creative spark.

</aside>

[***Learn more about 3M’s process here.***](<https://seekingalpha.com/article/4233863-durability-of-innovation-3m>)